A Forging Engineer's Guide to Modern Nitride Case Hardening for H13 Dies

As a forging engineer, I've spent considerable time analyzing a critical issue: maximizing the life of hot-work tooling, especially when forging high-temperature stainless, titanium, zirconium, and inconel alloys. We’ve all seen dies pulled prematurely due to excessive wear and heat checking. My team recently had a particularly frustrating experience with a salt bath nitrided die that failed by flaking after multiple heat cycles, which prompted a deep dive into the current state of case hardening.

This isn't just about chasing incremental gains; it's about fundamentally improving our process reliability. I want to share my findings on the leading surface treatments and provide a clear rationale for why some modern methods are far superior for our demanding applications.

The Physics of Failure in Hot Forging

Before we can select the right solution, we must correctly define the problem. Our H13 dies fail due to a combination of three primary mechanisms:

Thermal Fatigue (Heat Checking): This is the dominant failure mode. The die surface is subjected to incredible thermal shock—from a few hundred degrees to over 2100°F and back down, in seconds. This cycle creates tensile stresses that initiate and propagate a network of fine cracks.

Abrasive and Adhesive Wear: Hot-formed stainless steel has a tenacious, hard oxide scale that acts like sandpaper, causing abrasive wear. Simultaneously, the intense pressure and heat can cause micro-welding between the workpiece and the die, a phenomenon known as adhesive wear or galling.

Thermal Softening: If the die's surface temperature exceeds its tempering temperature for a sufficient duration, it will soften. This loss of hot hardness leads to plastic deformation and a loss of dimensional integrity, often called "washout."

A successful surface treatment must directly counter these forces.

The Microstructure of a Successful Surface

The key to a durable die surface lies in understanding its two distinct zones after nitriding. This is where our past failures with salt bath nitriding became clear.

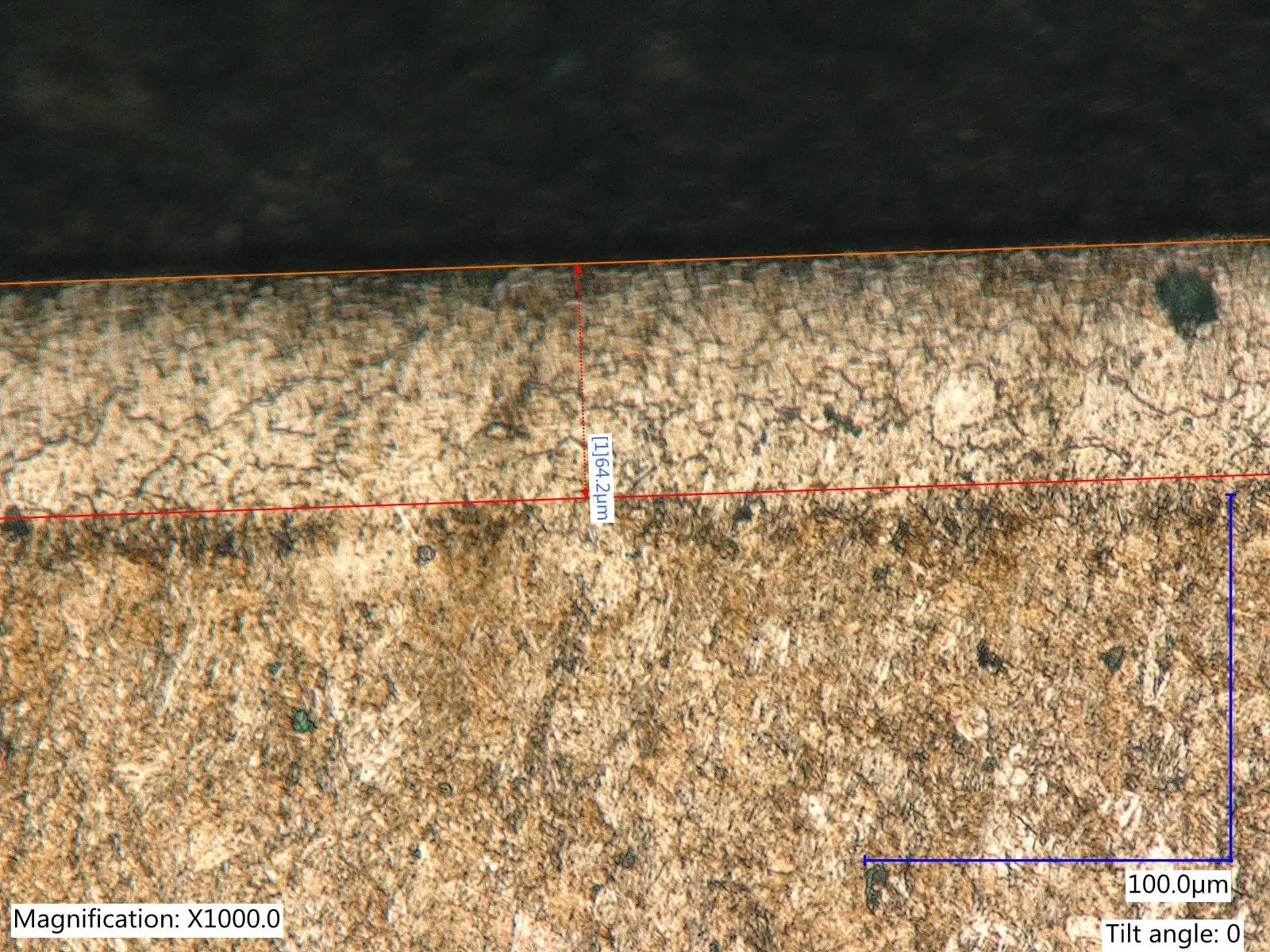

The Compound Zone (The "White Layer"): This is the outermost layer, composed of iron nitrides. It provides excellent hardness and wear resistance. However, if this layer is too thick, porous, or composed of the wrong phase, it becomes extremely brittle. This is what flaked off our die; it was a structural weakness, not a strength.

The Diffusion Zone: Beneath the compound zone, nitrogen atoms diffuse into the steel matrix. This doesn't just increase hardness; it creates a deep region of high compressive residual stress. This is the most critical feature for combating heat checking. Cracks cannot easily open and grow in a material that is being actively squeezed together.

The goal of any modern process is, therefore, to engineer a thin, dense, and tough compound layer (for wear) supported by a deep, highly compressed diffusion zone (for fatigue resistance).

Evaluating the Modern Case Hardening Processes

With this understanding, let's critically evaluate the available technologies based on their ability to control the surface microstructure.

Plasma (Ion) Nitriding / Nitrocarburising: This process is performed in a vacuum chamber, using ionized gas (a plasma) to precisely deliver nitrogen and/or carbon to the die surface. It offers an unparalleled level of control. We can specify the exact thickness and phase of the compound layer, or even eliminate it entirely to create a "diffusion-only" case. The addition of carbon in nitrocarburising is particularly effective against the adhesive wear we see with stainless steel. This is a top-tier solution.

Controlled Gas Nitriding / Nitrocarburising: Modern furnaces with advanced sensor technology allow for the precise control of the gas chemistry, or "nitriding potential." This gives us excellent command over the resulting microstructure, nearly on par with plasma. It is exceptionally good for treating large batches or dies with complex internal geometries that might be challenging for plasma's "line-of-sight" nature. This is also an excellent, highly recommended option.

Corr-I-Dur®: This is a proprietary gas nitrocarburising process from Bodycote that includes a final post-oxidation step. This creates a unique surface with a hard carbonitride layer for wear resistance, topped by a thin, black oxide layer that acts as a superb barrier against galling. For applications where adhesive wear is the primary concern, this specialized process is a very strong contender.

Fluidised Bed Nitriding: This method uses a heated retort of fine ceramic particles suspended by flowing gas. It offers the rapid, uniform heating of a liquid bath but with the superior atmospheric control of a gas process. It is a significant upgrade from salt baths and provides good, reliable results, though perhaps without the pinpoint precision of the most advanced plasma or controlled-gas systems. A solid, viable alternative.

Salt Bath Nitriding: This is the legacy process. While effective for general hardening, it offers very little control over the chemical reaction at the die surface. This lack of control is what leads to the formation of a thick, brittle compound layer that is prone to flaking under thermal shock. For critical, high-stress applications like ours, this process is now considered obsolete and presents an unacceptable risk of premature failure.

Recommendation and Path Forward

Based on the evidence, the industry consensus is clear: processes that offer precise microstructural control are essential for high-performance hot forging dies.

My primary recommendation is to adopt either Plasma Nitrocarburising or a modern, potential-controlled Gas Nitrocarburising process. Both technologies provide the necessary control to create a tough, fatigue-resistant surface that will not flake. For our stainless steel lines, Bodycote’s Corr-I-Dur® also warrants serious consideration due to its anti-galling properties.

Moving forward, our technical specifications to any heat-treat vendor must be rigorous and non-negotiable. We will explicitly require:

A maximum compound layer thickness (e.g., <10 µm) that is dense and non-porous.

A specified minimum diffusion zone depth (e.g., >0.15 mm) and surface hardness (e.g., >950 HV).

Certification with every batch, including a photomicrograph and a microhardness traverse plot to verify the results.

By shifting our focus from simple surface hardness to the precise engineering of the entire case structure, we can move from reactive maintenance to a proactive strategy of building longer-lasting, more reliable tooling.

Ask me anything.

Have a question? Want some more information? Need some homework help? Fill out the form and get in touch!